Advantages and operation of combined punching and shearing machine

Release Time:

Sep 02,2024

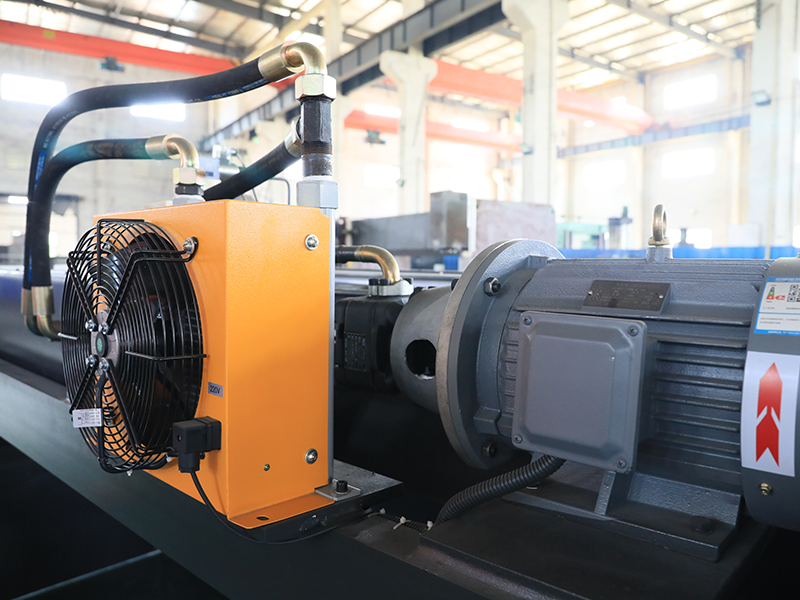

The combined punching and shearing machine integrates intelligent mechanical equipment, mainly including metal cutting, steel plate processing, punching machine, and sheet metal bending. It is easy to use in the operation process, low energy consumption, low maintenance cost, and effective asset saving.

The combined punching and shearing machine integrates intelligent mechanical equipment, mainly including metal cutting, steel plate processing, punching machine, and sheet metal bending. It is easy to use in the operation process, low energy consumption, low maintenance cost, and effective asset saving. It is an ideal equipment for precision processing in the intelligent processing industry; it is widely used in steel structure processing, hardware processing, grain machinery casing and large parts processing, thresher template support, trailer bucket machinery parts processing, etc. There are many types of punching and shearing machines on the market, mainly including hydraulic press combined punching and shearing machine, double-linked ... Combined punching and shearing machine, etc.; the equipment has a compact structure, superior performance, exquisite appearance, convenient use, and safe use;

The operation process of the combined punching and shearing machine, first check the switch power supply, and proceed to the next step when the air switch is intact and the working voltage is stable; the next step is to open the equipment wiring cabinet for wiring, and then close the cabinet door; the fourth step is to step on the foot switch. If the equipment does not respond, the switch power supply can be replaced with the emergency stop button turned off; then the power supply needs to be turned off when the mold is disassembled and replaced at work, that is, after the work is completed, turn off the switch power supply and remove the debris.